Brush Gun Series

Features of Brush Gun

By the synergy of Pulse Air Spray and Brush Vibration, it can be realized the powerful cleaning.

Product Index

- Brush Gun Series

- Precision Cleaning Brush Gun

- General Cleaning Brush Gun

- Pen Type Brush Gun

- Flexible Brush Gun Series (Brush length adjustable)

- Special Brushes

- Deburring Brush Gun

- Pencil-Type Static Eliminating Brush Nozzle

- Static Electricity Removal Brush Gun

- Lens Cleaner

Precision Cleaning Brush Gun

The Precision Cleaning Brush Gun can be realized the powerful cleaning by the synergy of Pulse Air Spray and Brush Vibration. It can remove the chips and the dusts in tiny space. It is suitable for the cleaning of the vehicles.

In case of semi-dry cleaning, dip the brush in the water, and pull the trigger in the air, and moderately reduce the moisture of the brush, then wash the objects. In case of static electricity removal, semi-dry cleaning is effective. Usually, for the stains of coffee or juice on a carpet, you have to wipe with wet mop. The Brush Gun beats the carpet with Pulse Air and adsorbs the dirt with brushing.

| Type | SB-300-35(Straight hair type) SB-300-35FB(Wavy hair type) |

| Air Pressure | 0.4 to 0.8 MPa |

| Air Flow Rate | 175 L/min. at 0.5 MPa |

| Weight | 90 grams |

| Brush Material | Nylon |

| Connection Part | R1/8 |

| Type | SGB-300-35 (Straight hair type) SGB-300-35-FB (Wavy hair type) |

| Air Pressure | 0.4 to 0.8 MPa |

| Air Flow Rate | 175 L/min. at 0.5 MPa |

| Weight | 320 grams |

| Brush Material | Nylon |

| Connection Part | Male coupler (Cupla) : 1/4 |

Demonstration of Oyster shell cleaning (1 min. 50 sec.)

- Application Example

- Cleaning and Raising of Velour or Carpet

- The dirt and dust accumulates on the air conditioning vents

- The dirt and the dust removal on the sash

- Dust removal on wallpaper

- Cleaning of the automobile and the motorcycle parts

- Cleaning of through hole circuit board and cutting section after press working

- Cleaning of the seats of the cars and buses

Precision Cleaning Brush Gun flyer (PDF: Approx. 800 KB)

About the difference between SB-300-35 and SB-300-35-FB

The brush of SB-300-35/SGB-300-35 has moderately stiff straight hair. It is suitable for cleaning of inside the vehicle.

The brush of SB-300-35-FB/SGB-300-35-FB has wavy hair. It is suitable for cleaning for dust removal without damaging, and for complex portion of the machines.

General Cleaning Brush Gun

Brush Gun was originally developed for circuit board cleaning, and it is convenient and easy to use. Currently, our customers use it extensively in other fields, such as textiles and air conditioning vents.

The concept of this product is : If it is used for non-precision equipment, the cost can be reduced, and we can modify to more suitable cleaner. To enhance the cleaning ability by brush vibration, the number of hairs is reduced.

| Type | SGB-300B (with Gun) SB-300B (Nozzle Unit) |

| Dimensions | W47 D264 H170 (with Gun) W47 D169 H47 (Nozzle Unit) |

| Air Pressure | 0.4 to 0.8 MPa |

| Air Flow Rate | 165 L/min. at 0.5 MPa |

| Weight | 300 grams (with Gun) 70 grams (Nozzle Unit) |

| Brush Material | Nylon (Straight hair) |

| Connection Part | Male coupler (Cupla) : 1/4 (with Gun) R1/8 (Nozzle Unit) |

- Application Example

- Automobile and motorcycle parts cleaning

General Cleaning Brush Gun Flyer (PDF: Approx. 210 KB)

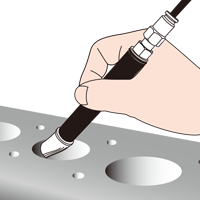

Pen Type Brush Gun

This is the small-diameter pen type brush gun which is suitable for detailed work such as dust or chip removal of small narrow gaps or in the groove.

Using the optional foot switch will dramatically improve the workability.

| Type | SB-20S SB-35S |

| Air Pressure | 0.4 to 0.8MPa |

| Weight | SB-20 : 76 grams SB-35 : 85 grams |

| Brush Material | Nylon |

| Connection Part | R1/8 |

*We also have models with guns. (SGB-35S/SGB-20S)

- Application Example

- Circuit board cleaning

- Car cleaning

- Fine burrs removal

- Chip removal

- Cleaning of food-related equipment

Flexible Brush Gun (Brush length adjustable)

The latest brush gun which enables the repulsion adjustment of the brush.

The Flexible Brush Gun is the latest model in the brush gun series. It has enabled the repulsion adjustment of the brush by slide type outer cylinder which is newly adopted.

The brushes can be easily replaced according to the application.

*Replacement brushes are sold separately.

We have a “Pen type” and a “Standard type” which diameter of the brushes vary.

| Type |

|

| Weight |

|

| Air Pressure | 0.4 to 0.8MPa |

| Air Flow Rate | 160 L/min. at 0.5 MPa |

| Operating Temperature | 10 to 50 °C (50 to 122 °F) |

| Connection Part | R1/8 (Nozzle Unit) Male coupler (Cupla) 1/4 (with Gun) |

Optional extra : One-touch connector socket (6mm/8mm), Air tube, Foot switch

Flexible Brush Gun flyer (PDF: Approx. 620 KB)

Deburring Brush Gun

Remove fine burrs with double effect

Deburring Brush Gun is a fine burr remover for metals and plastics processing. It works with a shock wave of pulse air generated by specialized nozzle and high speed vibrating abrasive brush.

It can remove the fine burr and the fine powder, quickly and efficiently.

Remarkable durability, Specially Selected Brushes

The brush is mixed with abrasive grain of Alumina and Silicon Carbide based on nylon. This brush has excellent strength, durability, and has chemical resistance, and also has an excellent grindability.

| Type |

|

| Air Pressure | 0.4 to 0.8 MPa |

| Air Flow Rate | 175 L/min. at 0.5 MPa |

| Weight | 320 grams (with Gun) 90 grams (Nozzle Unit) |

| Operating Temperature | 10 to 50 °C (50 to 122 °F) |

| Connection Part | Male coupler (Cupla) : 1/4 (with Gun) R1/8 (Nozzle Unit) |

- Application Example

- Fine burr removal for metals and plastics processing

Deburring Brush Gun flyer (in Japanese, PDF: Approx. 300 KB)

About the difference between Alumina and Silicon Carbide

- Alumina (SGB-A/SB-A)

- It is a rugged shape abrasive, and has moderate grinding force and excellent durability.

- Silicon Carbide (SGB-C/SB-C)

- It is a sharp shape and hard abrasive, and has excellent grinding force.

Pencil-Type Static Eliminating Brush Nozzle

Both Static Elimination and Air Blow can be done!

The “Pencil-Type Static Eliminating Brush Nozzle” is a refined tool that combines a brush and an air blow nozzle. It is designed to effectively remove static electricity and dust using conductive fiber brushes. The “Standard Type” and the “Adjustable Type” are available.

These innovative nozzles can eliminate static without using anti-static agents. They demonstrate exceptional efficiency in removing dust and cutting debris from resins that are prone to static charging. The brush is composed of “organic conductive fibers.” These fibers have the unique ability to discharge static electricity independently, with no need for an external power supply or grounding.

The “Adjustable Type” has a sliding outer cylinder, which can adjust the brush's rebound force and stiffness according to their specific requirements. This feature enhances the versatility and adaptability of the nozzle.

| Type | Standard Type : SB-35-TR Adjustable Type : SB-35-TR-SL |

| Dimensions (mm) | Standard Type : W20 D155 H20 Adjustable Type : W35 D155 H35 |

| Weight | Standard Type : 45 grams Adjustable Type : 70 grams |

| Air Pressure | 0.3 to 0.5MPa |

| Brush Materials | Nylon and Organic Conductive Fibers (mixed) |

| Connection Part | R1/8 |

Static Electricity Removal Brush Gun

Add the effect of static electricity removal !!

Static Electricity Removal Brush Gun can remove the chips of the manufacturing process with the peeling effect of Pulse Air and Brush Vibration.

The material of the brush is Monoeight, it is nylon mixed with conductive carbon black. It is effective for anti-static.

It is suitable for dust removal and cleaning of cutting process of plastics, dust removal of films, papers and polystyrene products, dust removal and cleaning in flammable area, and cutting section cleaning after press working.

| Type | SGB-300-35-CB (with Gun) SB-300-35-CB (Nozzle Unit) |

| Air Pressure | 0.4 to 0.8 MPa |

| Air Flow Rate | 175 L/min. at 0.5 MPa |

| Weight | 320 grams (with Gun) 90 grams (Nozzle Unit) |

| Brush Material | Carbon Monoeight (Conductive fibers) |

| Connection Part | Male coupler (Cupla) : 1/4 (with Gun) R1/8 (Nozzle Unit) |

- Application Example

- Dust removal and cleaning of cutting process of plastics

- Dust removal of films, papers and polystyrene products

- Dust removal and cleaning in flammable area

- Cutting section cleaning after press working

- Catalog

- -

Lens Cleaner

It is suitable for removal of iron particles inside the ring-shaped magnet, removal of dust and cleaning of lens, sensor and LED.

| Type | SGB-90-KV (with Gun) SB-90-KV (Nozzle Unit) |

| Air Pressure | 0.4 to 0.8 MPa |

| Air Flow Rate | 180 L/min. at 0.5 MPa |

| Weight | 300 grams (with Gun) 70 grams (Nozzle Unit) |

| Brush Material | Heat resistant, high strength aramid fibers |

| Connection Part | Male coupler (Cupla) : 1/4 (with Gun) R1/8 (Nozzle Unit) |

- Application Example

- Removal of iron particles inside the ring-shaped magnet

- Lens, Sensor and LED

- Dust removal, cleaning

- Catalog

- -

Specifications and appearance of our products may change for the purpose of improvement without notice.

Adobe, Acrobat, Acrobat logo are trademarks of Adobe Systems Incorporated.

Kevlar® is a registered trademark of DuPont USA.

Cupla® is a registered trademark of Nitto Kohki Co., Ltd.